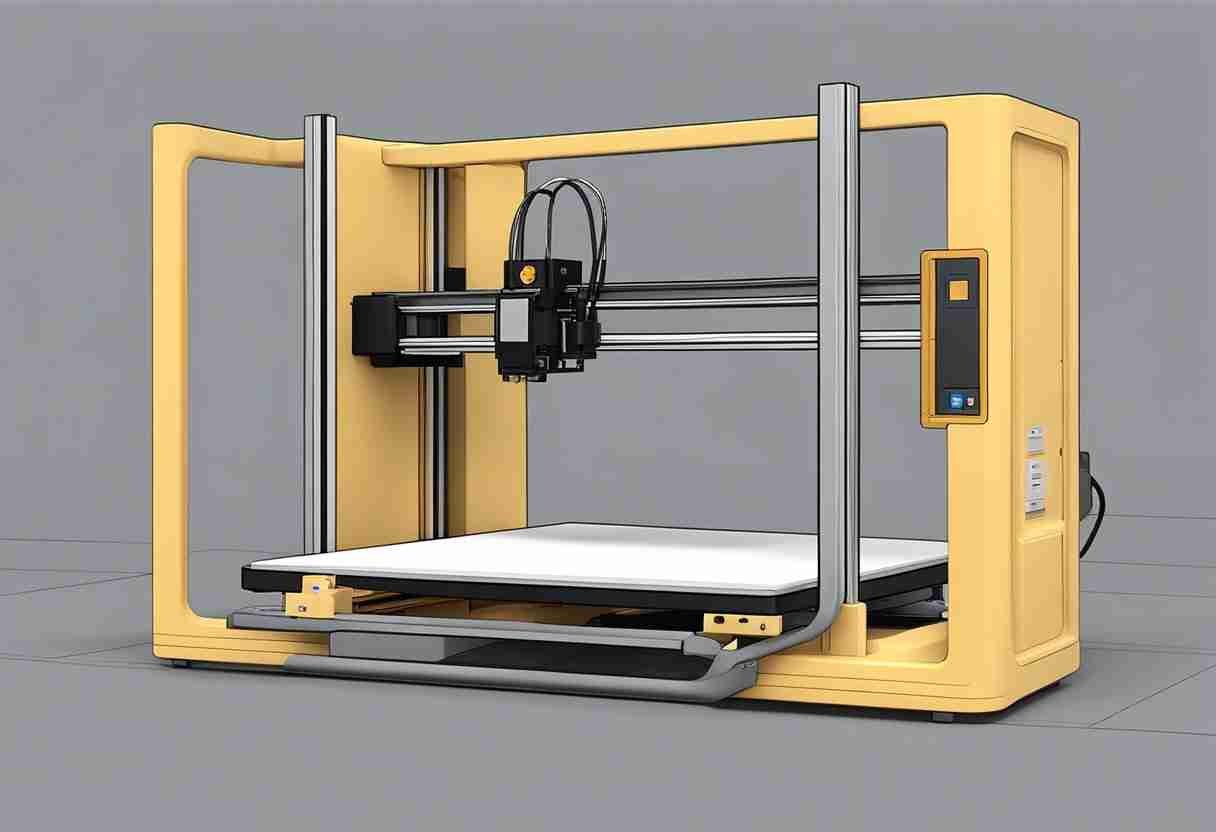

PEI 3D printing refers to a manufacturing process where parts are constructed layer by layer using a filament made from Polyether Imide (PEI), a high-performance engineering thermoplastic. PEI material is known for its strength, rigidity, and thermal stability, particularly for applications requiring durability and heat resistance. The printing process using PEI is similar to that of other thermoplastics; however, it stands out due to the material's ability to withstand higher temperatures and its inherent flame resistance, making it a preferred choice for aerospace, automotive, and electronic industry components.

One of the main advantages of PEI in 3D printing is the high quality of the parts produced, with excellent mechanical properties and dimensional stability. Additionally, the surface finish of PEI-printed objects is remarkably smooth, which is beneficial when a high aesthetic standard is required. Despite these benefits, there are challenges to consider, such as the need for a heated print bed and an all-metal extruder to handle the high extrusion temperatures typically required for PEI filament.

The attractiveness of PEI is also found in its consistent adhesion during printing. PEI sheets are often applied to the build platform to improve bed adhesion and simplify printing. This ensures prints remain firmly in place without additional adhesives or tapes, streamlining the printing process and yielding high-quality results. Whether working with a smooth or rough surface PEI sheet, creators find that this material addresses many common issues associated with 3D printer print beds, ensuring that PEI continues to grow in popularity within the 3D printing community.

Understanding PEI in 3D Printing

PEI, or polyether imide, is a thermoplastic known for its robustness and ability to endure high temperatures, making it a key player in advanced 3D printing applications.

Properties of PEI Material

Polyether imide (PEI) is a high-performance thermoplastic with excellent mechanical properties. It remains stable under prolonged exposure to high temperatures and exhibits significant chemical stability. This material's high-temperature stability makes it suitable for applications that experience extreme heat, maintaining its integrity where others fail. PEI's high wear resistance contributes to its longevity and reliability in demanding environments.

PEI Surface Benefits

The advantages of a PEI surface in 3D printing are noteworthy. Firstly, it enhances adhesion during printing, ensuring parts are secure and accurately rendered. Additionally, its smooth finish contributes to the quality of the printed object. Due to its resistance to high temperatures, a PEI print bed can be heated without concern for deterioration, ensuring a consistent print environment.

Types of PEI Applications

Due to its resilience and longevity, PEI is utilized in various 3D printing applications. Its ability to withstand high temperatures and stresses in the aerospace industry makes it an ideal choice for components. In the medical field, its chemical stability ensures that it can handle the rigors of sterilization without degrading. As a result, PEI has found its way into surgical instruments and devices. In electronics, PEI's properties are advantageous for producing parts that must resist wear and sustain performance over time.

PEI Bed Adhesion and Surface Preparation

Achieving adequate bed adhesion and surface preparation is critical for successful 3D printing with a PEI sheet. A well-prepared PEI print surface aids in improving adhesion, ensuring prints stick during the printing process and can be removed with ease upon completion.

Adhesives and Alternatives

PEI sheets serve as a build surface that offers strong adhesion without additional adhesives. For users who experience adhesion issues, applying a thin layer of glue stick to the PEI surface can improve grip, especially for prints with a large footprint. However, one of the key advantages of PEI is that it typically negates the need for such substances due to its high-temperature resistance and excellent thermal properties, which ensure a strong bond with the plastic as it cools down.

Surface Cleaning Methods

Regular cleaning of the PEI sheet is paramount for optimal performance. A common method involves wiping the surface with a soft cloth dampened with isopropyl alcohol (IPA). This removes grease and other contaminants that can prevent good adhesion. For more thorough cleaning, slightly heating the bed and then using IPA can increase the efficacy of the cleaning process.

- Weekly Maintenance: Wipe with 70% or higher IPA

- As Needed Basis: Scrub with a non-abrasive sponge

Maintenance and Longevity

To maintain the longevity of a PEI print surface, it's crucial to avoid scratches and dents by using non-abrasive tools for print removal. The PEI sheet should be replaced once it shows signs of wear or if prints no longer adhere effectively. It's also important to note that PEI has high and low-temperature resistance, making it suitable for a wide range of materials and ensuring durability over time. Regular inspections for signs of wear ensure the build surface remains reliable for consistent use.

Printing With PEI: Techniques and Tips

When incorporating Polyetherimide (PEI) sheets as a print bed surface in 3D printing, understanding the nuances of bed temperature control, filament compatibility, and troubleshooting is crucial for achieving optimal print quality.

Optimizing Bed Temperature

PEI print beds require precise bed temperature settings to ensure superior adhesion and print quality. The ideal bed temperature can vary depending on the type of filament used. ABS usually adheres well to PEI at temperatures around 110°C, while PLA can print successfully at lower temperatures, typically near 60°C to 70°C. Maintaining an even temperature across the bed is vital, and tests are recommended to determine the most effective temperature for each specific printing filament.

Filament Choices and Settings

When selecting printing filaments for PEI, one's choices can significantly affect the print service performance. Filaments such as PLA and ABS are known for their excellent heat resistance and adhesion properties to PEI surfaces. For these materials, nozzle temperatures are generally set at around 200°C for PLA and 230°C for ABS. It's important to adjust the nozzle height accurately to ensure the first layer is firmly pressed onto the PEI surface without being so close as to damage it.

Troubleshooting Common Issues

Encountering issues during the 3D printing process using PEI beds is not uncommon; however, they can usually be resolved with some adjustments:

- Warping: If the corners of a print lift or warp, increasing the bed temperature by a few degrees can help.

- Adhesion: Cleaning the PEI surface with isopropyl alcohol can improve adhesion, and light sanding can rejuvenate aged PEI surfaces.

- Removal: Some users encounter difficulty when removing finished prints. Waiting for the bed to cool down can facilitate easier removal without damaging the PEI sheet or prints.

By paying attention to these specific aspects of PEI 3D printing, users can enjoy a smoother printing experience and consistently high-quality results.